- January 11, 2019

- 0 Comments

- In Occupant Health & Wellness

- By Steven Winter Associates

Quick pulse survey: in the last three months, since we published our Part I blog on tips for healthier indoor environments, how many of you have either incorporated some of our healthy recommendations into your home, or informed your clients on the most effective ways to address health risks in buildings (hint: if you need a refresher, please visit Part I)?

As previously discussed, there is overwhelming evidence for the business case for healthier buildings, from greater employee productivity and reduced sick days in the workplace to reduced asthma incidents and ER visits for children living in green housing. Leading organizations know that improved wellbeing helps employees to be healthier and lowers healthcare costs. It also helps employees to be more productive, creative and innovative, and less likely to leave for a competitor. The same concept can be applied to tenants in rental buildings and condos.

Before we dive into health tips #6-10, here are some fun (and not so fun) facts to keep in mind while we spend winter days INSIDE our workplaces, schools and homes:

In the winter, school-aged children ages 11-17 will spend 60 minutes a day outdoors, compared to 175 minutes in the summer. (Source: Schools for Health by the Harvard TH Chan School of Public Health.)

In the winter, school-aged children ages 11-17 will spend 60 minutes a day outdoors, compared to 175 minutes in the summer. (Source: Schools for Health by the Harvard TH Chan School of Public Health.)- In a study of 73 elementary schools in Florida, students in schools cooling with the noisiest types of HVAC systems were found to underperform on achievement tests compared with students taking tests in schools with quieter systems.

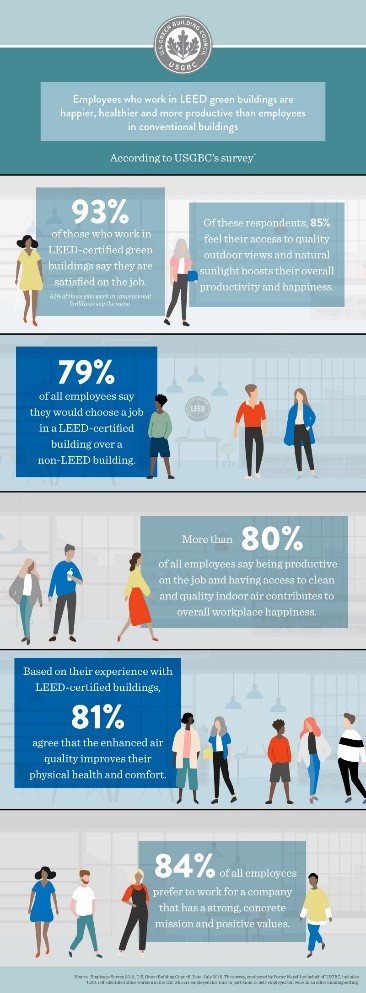

- According to a recent survey released by the U.S. Green Building Council (USGBC), employees who work in LEED certified green buildings are happier, healthier and more productive than employees in conventional and non-LEED buildings:

- More than 90 percent of respondents in LEED certified green buildings say they are satisfied on the job and 79 percent say they would choose a job in a LEED certified building over a non-LEED building.

- More than 80 percent of respondents say that being productive on the job and having access to clean, high-quality indoor air contributes to their overall workplace happiness.

- 85 percent of employees in LEED certified buildings also say their access to quality outdoor views and natural sunlight boosts their overall productivity and happiness, and 80 percent say the enhanced air quality improves their physical health and comfort.