- January 26, 2018

- 0 Comments

- In Existing Building Performance

- By

Steam pressure gets a disproportionate amount of attention. That’s partially due to the common, but not necessarily true idea that higher pressure equals more fuel use. Remember, it’s not the steam’s pressure that heats the building; it’s the steam’s heat energy. In fact, you can heat a building with 0 psig steam. You can even heat a building with a boiler that’s too small and never builds positive pressure. You can’t do it well, but you can do it.

System Operation

Thanks to the law of conservation of energy, we know that energy cannot be created or destroyed — it can only be altered from one form to another. In a steam heating system, the flow of energy goes like this:

- The boiler transfers Btus from the fuel to the steam (energy input).

- The steam transfers those Btus to the rooms.

- The rooms transfer those Btus to the outdoors (heat loss, aka the load).

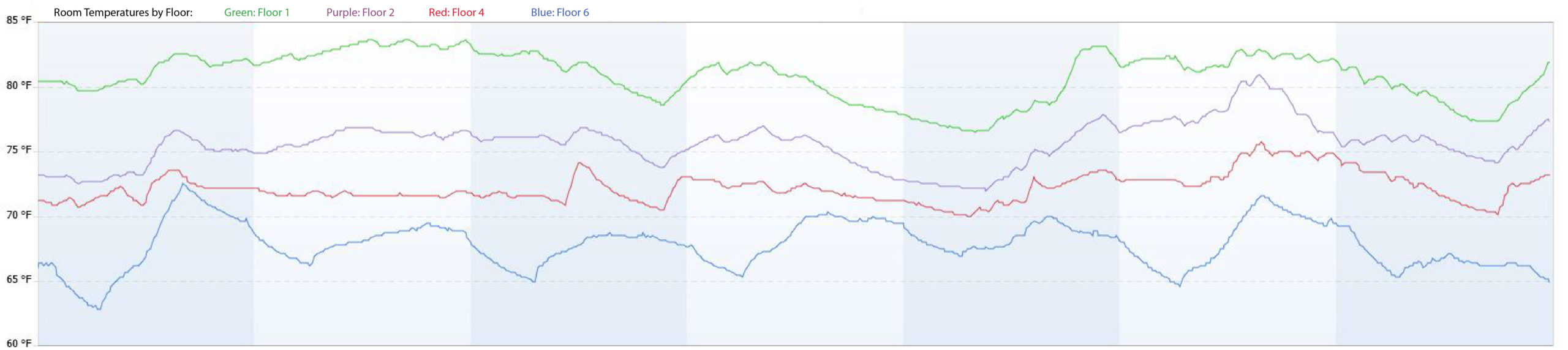

It’s important to keep this energy flow in mind because they are linked and self-equalizing. If the energy input exceeds the heat loss, the building temperature will increase, which, in turn, increases the heat loss. And, a building’s heat loss depends on the temperature difference between inside and outside and the amount of air transfer occurring. So, the best way to keep the heat loss down is to keep the indoor temperatures as low as possible, and keep the windows closed. Furthermore, in an apartment building, the coldest room drives the load in any steam-heated building and the Super needs to send enough heat around to satisfy the hardest-to-heat apartment.

When faced with an unbalanced distribution, Supers often crank up the pressure in an attempt to force heat to those cold apartments, which are cold because the system is air-bound. In this case, pressure has a direct impact by increasing the system’s venting rate. When the steam pressure goes from 1 psig to 5 psig, the pressure difference across the air vents and steam traps goes up by 500%. Therefore, increasing the pressure is an attempt to overcome the common problem of air-bound systems.

It is true that these buildings use a lot of unnecessary energy for heating, but it’s not because of the operating pressure. It’s the air problems that ultimately result in energy waste by leaving some apartments cold while overheating the rest of the building. The same thing occurs if the Super lengthens the heating cycle in order to give more time for steam to reach those cold apartments — most of the building gets overheated. And then, windows get opened. Ultimately, this is a temperature problem, not a pressure problem. If the system is balanced and controlled so that air binding is no longer an issue, temperatures can stay reasonable and windows can stay closed. Less energy is consumed.

Eliminating overheating will reduce the amount of fuel consumed by the boiler, which needs to be the goal of any energy saving retrofit.

Claims that systems were designed to provide enough heat when there is 1 psig in the radiators are a red herring. The design conditions occur only ~1% of the time, and in any case, the heaters are far too large for today’s design heat loss. In many cases, these systems were sized to heat the apartments with the windows open in the dead of winter. We no longer keep our windows open all winter long, or at least we wouldn’t if we could control the temperature! In fact, a radiator full of 1 psig steam for a significant length of time will overheat a room, which is why these systems all need some form of temperature control. This can be a local control, such as a TRV, a central control that calls for heat based on indoor or outdoor conditions, or a combination of the two. Controlling room temperature is essential for saving energy.

As a thought experiment, consider Denver. It takes longer to make pasta there, since water boils at 202ºF a mile above sea level, as opposed to the 212ºF we have here. What would happen if we were to magically transport one of our steam-heated NYC buildings to Denver? Everything else would stay the same: the 80ºF average indoor temperature and the open windows. The only thing that changes is that steam, at any gauge pressure, is less hot. Would the building use less energy? Nope.

Steam Generation

So far we’ve been talking about the system operation. But what about the steam generation? Raising the pressure also raises the boiling point of water a bit, so there could be a change in the combustion efficiency of the boiler itself. However, in practice we’ve found burner tuning to be the big driver of combustion efficiency, and we haven’t seen any indication that boilers operating at 5 psig have lower efficiencies than those operating at 1 psig.

On the other hand, wet steam can wreak havoc on the distribution system by overwhelming the system with water and damaging components — factors that contribute to imbalance and energy waste. And, it is true that higher pressure steam is drier than low pressure, since it moves more slowly and causes less carryover when it leaves the boiler.

So, our point isn’t to say that pressure isn’t important at all; it does play a role in the distribution. In some cases, such as gravity-return two-pipe systems, too high pressure can prevent condensate from returning to the boiler. But that’s because pressure is affecting the distribution and overheating large parts of the building, not because the needle on the pressure gauge is pointing to any specific number.

We should be mindful that when it comes to steam, logic often flies out the window (which, conveniently, is often open). The saturated steam tables show us that pressure and temperature are linked, which is true, and that has morphed into the idea that high steam pressure equals overheating. But the temperature of the steam isn’t all that relevant, and even steam at a low pressure is more than you need. It’s the room temperature that matters, so we should focus more on eliminating air binding and balancing the distribution so that temperatures can be controlled, as opposed to worrying so much about what the operating pressure is.

Controlling pressure for its own sake should never be the end goal. It’s only important when looking to improve the distribution and balance of a steam system, that is, when it helps to control the room temperature. We’ll look at a few of the ways that controlling pressure can help you control temperature, and therefore save energy, in our next post.

By Jason Block, Engineering Director