SWA’s Enclosure Group is acutely aware that insulation is the most important single material choice to maximize the enclosure’s thermal resistance over its operational life. Many of us in the building industry believe that, combined with a good continuous air seal, the highest insulation value makes the greenest enclosure, helping to reduce a structure’s carbon footprint and combat climate change. It may come as a surprise, then, that some of the most commonly used insulation materials are so carbon-heavy to manufacture and/or install, that for many decades they wipe away the carbon-energy savings they are supposed to provide. The following is a detailed discussion of how and why this is, and what the industry is doing to change the equation.

Embodied vs. Operational Carbon

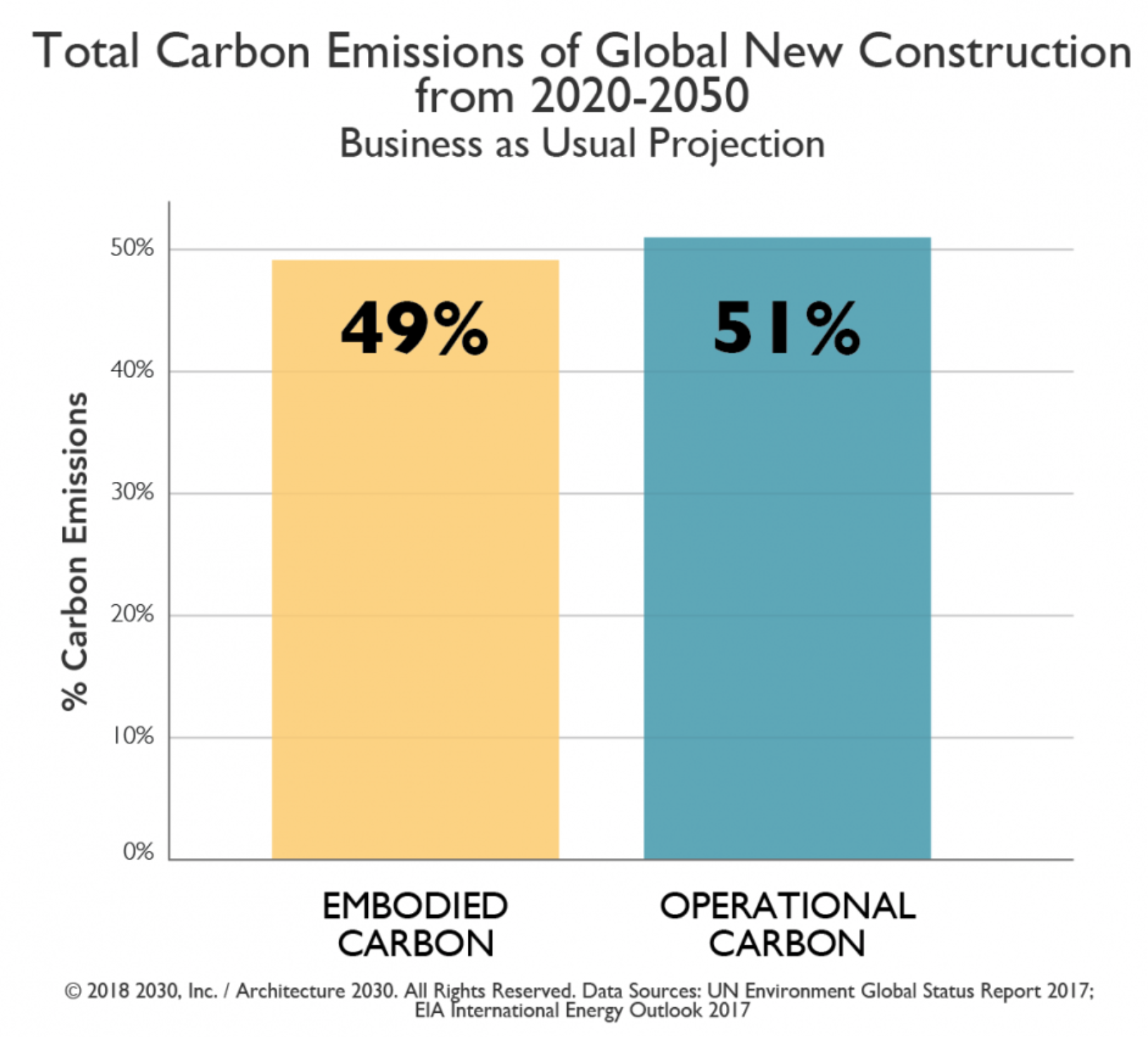

The built environment looms large in the climate picture, because almost 40% of the total carbon put into the planet’s atmosphere each year is attributed to buildings. Over the past 30 years of green building, we have overwhelmingly focused on operational carbon – the carbon that buildings emit as they are being used. Only recently have we begun to focus on embodied carbon – the carbon that goes into constructing buildings, which is typically far greater than the energy saved in the first decades of operation. Changes in energy codes are aimed at operational carbon, and even those organizations and standards that have been at the forefront of promoting sustainable building [LEED, PH] have not been quantifying or limiting embodied carbon, although they bring attention to it.

The Time Value of Carbon

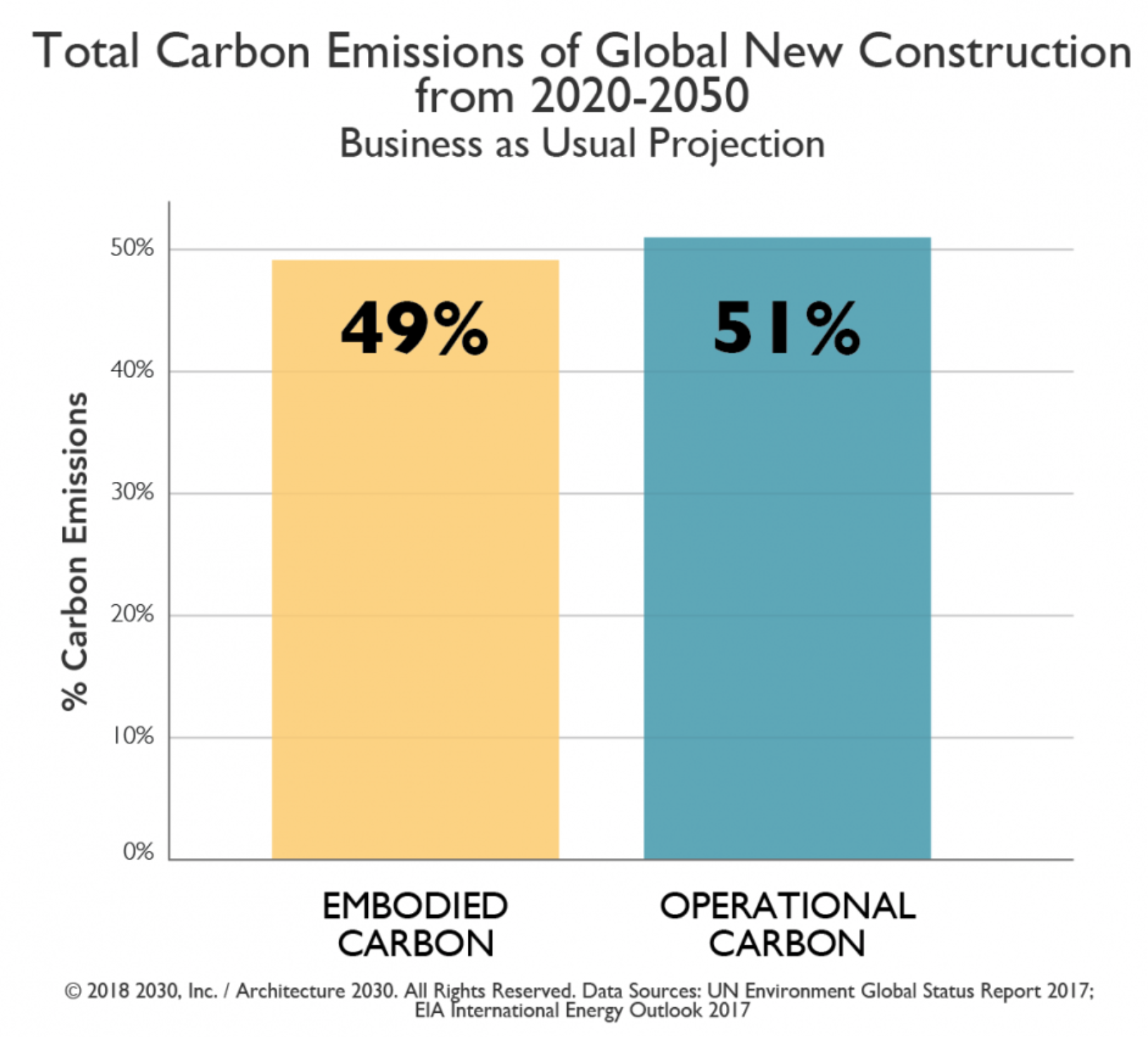

Assuming that a building stands for many decades, or even centuries, its operational carbon will eclipse its embodied carbon over its lifetime, and therefore when the building’s carbon Life Cycle Assessment (LCA) is calculated, operational carbon savings will be more important than embodied carbon saved/spent in the long run. Why does embodied carbon deserve equal weight with operational carbon? Because of the total global carbon emissions from buildings, 28% is pegged to embodied carbon. That’s already a large percentage, but when you consider the near term, the first 30 years of a building’s life, the percentage jumps to about 50%. In effect, every new building is in carbon debt upon completion due to the huge amount of carbon emitted in order to construct it., And in order for the climate to benefit from the energy savings provided by a well-insulated and sealed enclosure and a high efficiency energy system, the building needs to last and be used for a very long time. The problem is that we may not have 30 years, let alone 60, to pay off that carbon debt.

In the first 30 years of a building’s operational life, 50% of its total carbon emissions are still due to embodied carbon (Source: Architecture 2030)

(more…)