It is clear to see that the Passive House (PH) standard is here to stay! Across North America, more States, Provinces, and Municipalities are integrating PH into their building standards. One of the more recent adopters is the City of Toronto. In the most recent version of the Toronto Green Standard (TGS), the PH standard is offered as an alternative compliance path to TGS Tier 3, and with this alternative compliance path one obvious question comes to mind: What is the major difference in required component efficiency for a multifamily building in Toronto that is looking to meet either the PH standard or TGS Tier 3?

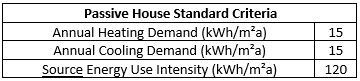

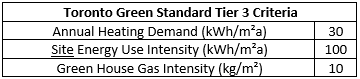

The PH standard is performance-based and is focused on decreasing whole building energy demand, improving building durability, providing optimal occupant thermal comfort, improving indoor air quality, and reducing carbon emissions. The PH standard reduces building operation costs, decreases carbon emissions, and supports an improved indoor environmental quality for building occupants. The TGS has similar goals and benefits when compared to the PH standard, and there are some obvious synergies in the program design between TGS and PH. The tiered energy category in the TGS takes a similar approach to PH by offering an annual budget for three different categories. For PH you must comply with a total energy budget for annual heating demand, annual cooling demand, and total source energy use intensity. Similarly, but slightly differently, the TGS offers a budget for total site energy use intensity (TEUI), annual heating demand or Thermal Energy Demand Intensity (TEDI), and the additional category of Greenhouse Gas Intensity (GHGI). In both standards, the path to compliance is non-prescriptive and designers can implement a variety of component efficiencies and system options. See table 1 and 2 below:

Table 1: Passive House Standard Criteria

Table 2: Toronto Green Standard Tier 3 Criteria

(more…)