Blog

There are always questions and concerns raised against building electrification ranging from initial cost to operating cost to reliability of the VRF technology. From the owner’s perspective, the biggest question is usually surrounding the operating cost of an electric system compared to a natural gas system for heating, but the cost of ownership must consider multiple energy metrics.

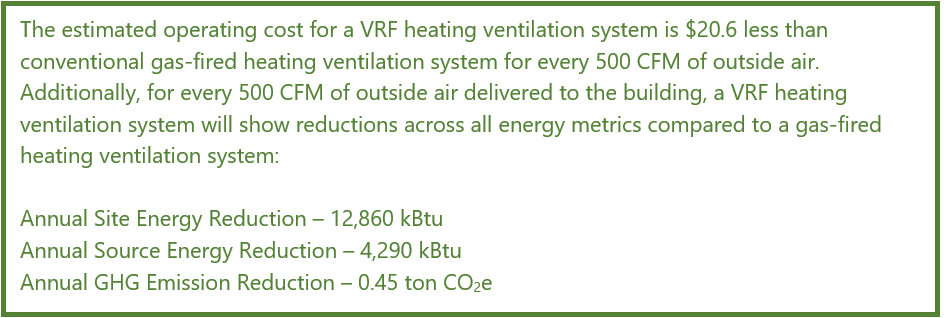

A common strategy to provide ventilation in multifamily buildings is to design a central roof-top air handler that distributes outdoor air to each unit. The energy cost for this system, which commonly uses natural gas for heating for either a gas furnace unit or hot water from a central boiler is paid for by the building owner. However, there is another option – Variable Refrigerant Flow (VRF) also known as Variable Refrigerant Volume. With the unprecedented rise of VRF technology in the last decade combined with regulations such as New York City’s Local Law 97 of 2019 (PDF) (carbon emission penalty), the industry is taking a giant leap towards building electrification. There are always questions and concerns raised against building electrification ranging from initial cost to operating cost to reliability of the VRF technology. From the owner’s perspective, the biggest question is usually surrounding the operating cost of an electric system compared to a natural gas system for heating, but the cost of ownership must consider multiple energy metrics. I was curious to understand the impact on various building energy profile metrics associated with a Dedicated Outdoor Air System (DOAS) using the conventional gas fuel source vs. the latest VRF heat pump technology using electricity in a multifamily building. The findings of this investigation challenge the deep-rooted notion that electricity, being more expensive than natural gas per BTU, will always cost more to operate.

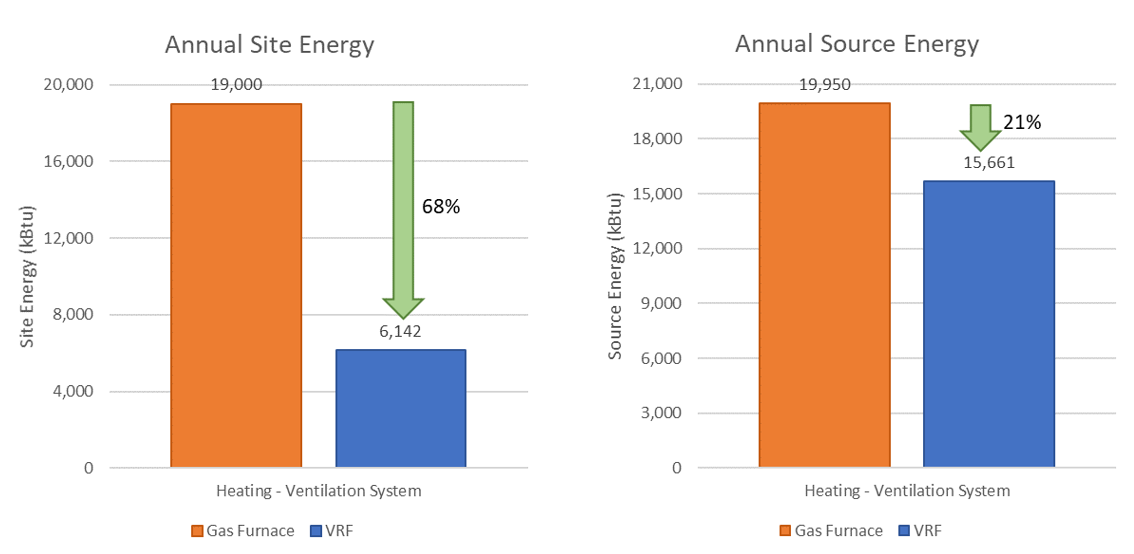

For the purpose of direct comparison between natural gas and electricity, this evaluation only looks at the space heating energy associated with the ventilation system. The higher cooling efficiency and heat recovery (simultaneous cooling and heating) capabilities of VRF technology will only lower the operating cost further compared to gas fired system. This additional savings has been ignored in this analysis. The energy analysis of the ventilation system has been evaluated using DOE-2 based eQUEST software. Below is the list of assumptions that were used to generate the energy model and simulate energy analysis:

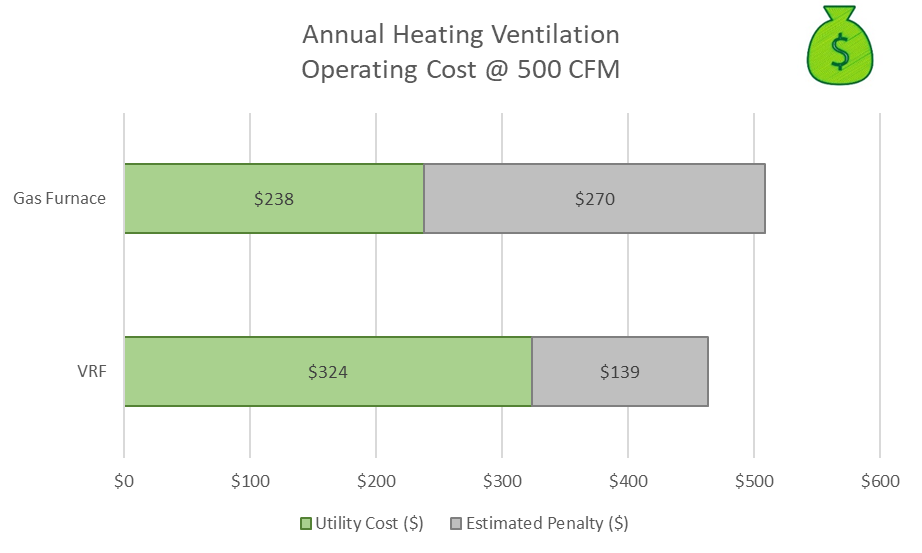

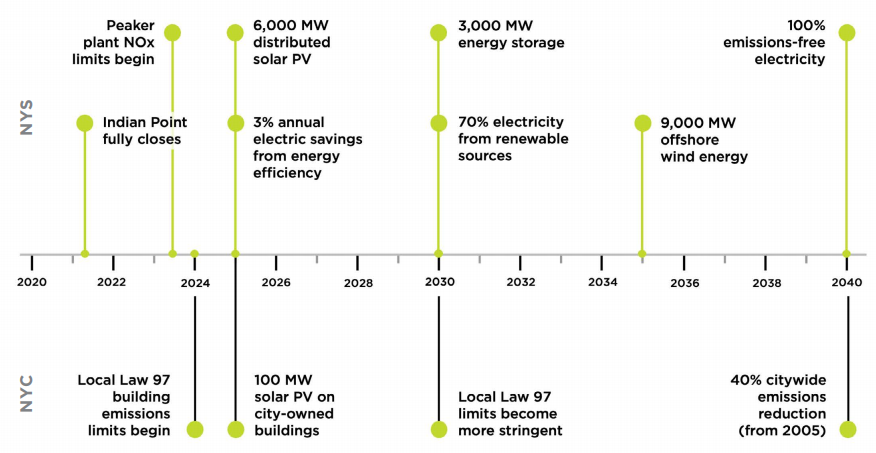

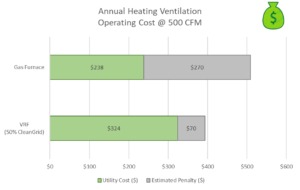

As shown in Figure 1, annual heating operating cost for a VRF ventilation system is lower than a conventional gas-fired ventilation system with current electric grid emission factors. The hidden penalty with the gas-fired system is that once the gas equipment is installed, it will emit constant greenhouse gas for the rest of its life span. However, as shown in the Figure 2 below cited by Urban Green Council in its report, ambitious city and state policies are driving toward more efficient buildings and a greener grid. As the electric grid gets cleaner, the GHG emission factor for electricity will reduce – thus resulting in less emissions and less carbon penalty every subsequent year.

A more renewable energy based electric grid, assuming 50% cleaner grid than today, will translate to an additional annual operating cost savings of $70 as shown in Figure 3.

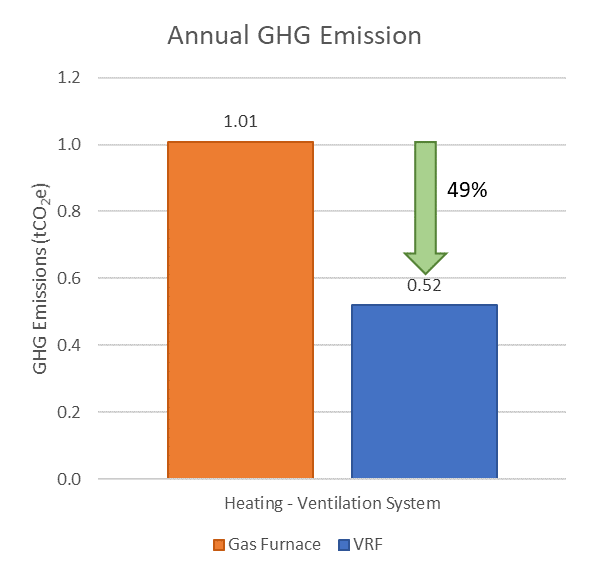

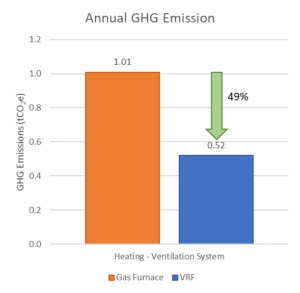

Furthermore, for every 500 CFM of outside air delivered to the building, the VRF heating ventilation system will show savings across various energy metrics compared to a gas-fired heating ventilation system. For the same amount of ventilation air delivered to the building, the VRF heating ventilation system shows 49%reduction in carbon emission compared to gas-fired system. The carbon emissions in the building can vary greatly depending on various factors, including construction quality, miscellaneous loads, occupant behavior, etc., which can or cannot be controlled directly by building owner. However, lower carbon emissions from a VRF ventilation system, may assist the building owner in maintaining desired carbon emission levels by providing enhanced flexibility in other building areas.

Contributor: Rahil Shah, Energy Engineer

Steven Winter Associates