- July 14, 2017

- 0 Comments

- In Existing Building Performance High-Performance Construction

- By Steven Winter Associates

About a year ago, I worked along with other HERS raters and the North American Insulation Manufacturers Association (NAIMA, a.k.a. Insulation Institute) to conduct a study on the importance of insulation installation quality and grading.

RESNET, the nation’s leading home energy efficiency network and the governing body of the Home Energy Rating System (HERS® Index) established standards for grading insulation installation.

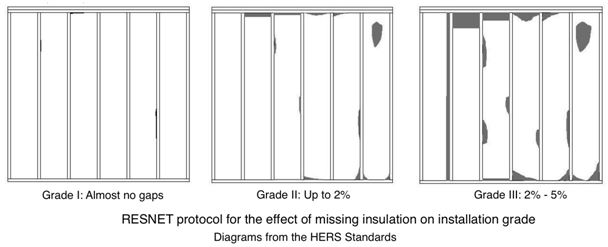

The grading is as follows:

Grade I— the best and nearly perfect install which includes almost no gaps or compression… what some would call “G.O.A.T.”

Grade II—allows for up to 2% of missing insulation (gaps) and up to 10% compression over the insulation surface area… what some would call “mad decent”.

Grade III—insulation gaps exceed 2% and compression exceeds 10%… anything worse and the insulated surface area is considered un-insulated.

Source: RESNET Mortgage Industry National HERS Standards

During the study, I suggested the Insulation Institute do a comparison on HERS energy models and how grading affects the overall efficiency, performance, and home indices. The result is indisputable; the difference between grade I and grade III insulation installation quality results in an average 4 point decrease to the HERS score. As a point of reference, the baseline HERS home is modeled assuming Grade I insulation, so anything less than grade I will automatically hurt the HERS score. Insulation surfaces categorized as Grade III are modeled such that there is no insulation R-value for 5% of the insulated surface area. Homes in the Northeast and cold climates get particularly harder score hits:

Source: RESNET Blog

To find out more about why builders and other industry professionals should care about insulation grades, follow the link to the RESNET blog above (includes registration link for a free webinar in August on the findings of the study) and watch the short animated video here.

The “business-as-usual” bottom line is always money, which is arguably the most compelling reason to take concern with insulation installation quality. Not installing Grade I insulation leaves money and energy wasted. While NAIMA argues that batt insulation is still the cheapest way to achieve Grade I insulation, it is traditionally the most difficult to get right. It is a lot quicker and simpler (especially for experienced labor/crews) to use a blown-in or spray product to achieve the Grade I standard, but there is a substantial added upfront cost when utilizing these batt-free insulation approaches. In addition, the health and environmental effects of these blown/sprayed products aren’t fully studied yet. The Insulation Institute aims to educate builders and contractors on effective batt installation in order to benefit from the material cost-savings of fiberglass and wool batts to consistently achieve Grade I quality.

As HERS raters, we are continually working to train and inform building professionals on best practices, no matter what material or product is being implemented. It’s our job to call out deficient work and to praise stellar work in order to continue to improve the built environment and the efficiency of homes. A third-party grading system helps ensure accuracy and manage quality.

By Carmel Pratt, Sustainability Consultant