BACKGROUND

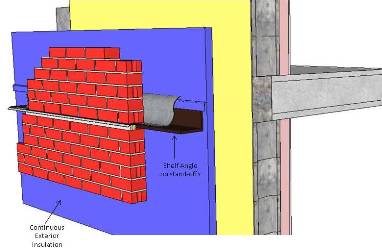

The multifamily building industry has adopted a best practice long touted by the building science community: continuous insulation at the exterior of the building. However, even in this ideal circumstance in which the insulation is installed flush and without gaps against the exterior substrate (concrete block or sheathing) with an air barrier applied to this substrate beforehand, the overall performance of the insulation will be vastly reduced by the installation of shelf angles.

Shelf angles (also know as relieving angles) are designed to support the expansion and contraction of the brick coursing; however, this presents a direct challenge to the continuity of exterior insulation. Standard design details interrupt the exterior insulation at every shelf angle, typically at every floor in line with window lintels. Since the shelf angle is made of steel, a highly conductive material, this interruption impacts not only the effectiveness of the insulation in general, it provides a considerable thermal bridge over the entire horizontal band of the building at every occurrence.

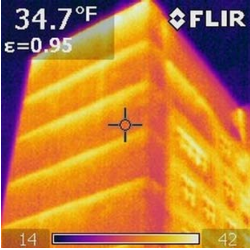

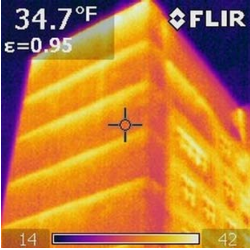

A recent article by Urban Green Council, “State Energy Code Clarification Will Stem Heat Loss through Walls,” made it clear that a continuous shelf angle has “about the same poor thermal performance as [an] exposed slab edge.” The full article can be read here.

Fig. 1. An infrared (IR) image that shows the thermal impact of shelf angles

SWA RECOMMENDATION #1: LIMITING SHELF ANGLES

Not all buildings require relieving angles. Building owners, architects, and structural engineers should first ask themselves whether relieving angles are necessary at all for the building being designed. If it is determined that these angles will be necessary, the next question the structural engineer should ask himself is what the minimum frequency necessary is to support the brick course. Generally speaking, buildings do not need one shelf angle per floor—despite this being common practice.

In addition to the aforementioned energy implications involved in specifying shelf angles, there are other benefits to eliminating these steel members when possible. The most obvious impact is on upfront costs. At approximately $25/foot of angle iron (via Union Iron Works), shelf angles for multifamily buildings in New York City can cost tens of thousands of dollars.

Upfront and operating (i.e. energy) costs aside, there is also the embodied energy of the material to consider. Not only does the manufacture of the steel angle contribute to its embodied energy, but also all of the energy used to transport these pieces to the project site. By reducing the need for the production of these angles, the overall energy expended to construct a new building decreases.

One additional consideration for owners is the maintenance required for shelf angles. The introduction of brick lintels creates an inherent and inevitable need for future maintenance. Since the cost of this upkeep is often considerable, owners may wish to use the opportunity to limit shelf angles during design to reduce long-term maintenance costs.

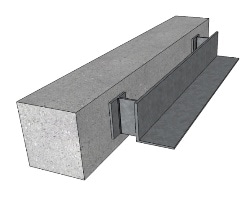

SWA RECOMMENDATION #2: OFFSETTING SHELF ANGLES

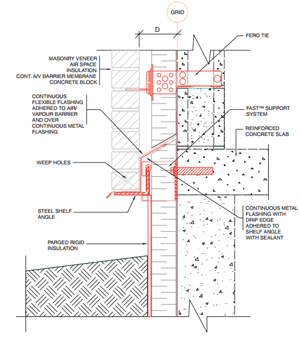

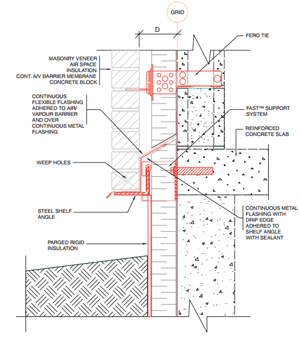

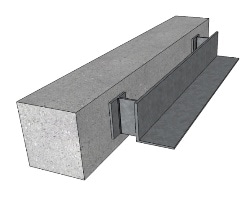

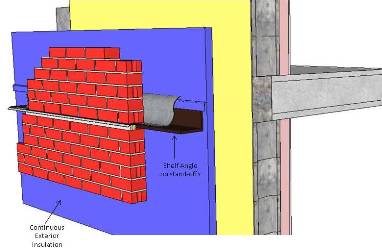

In addition to limiting their frequency, consider a shelf angle offset to further reduce thermal bridging. One such system that allows for this is manufactured by FERO called FAST (FERO Angle Support Technology).

Fig. 2. Typical FAST TM system detail

FAST is designed to offset the shelf angle from the structural backing, allowing the insulation and air barrier installations to be more continuous. More information about this product can be found on their website.

SWA welcomes the input of design teams for other possible solutions to achieve a more continuously insulated wall. By accomplishing this, the building will have a truly continuous thermal envelope. As a result, thermal bridging will be eliminated along with the associated energy losses.

Fig.3. An offset shelf angle

Fig.4. A wall section with an offset structural shelf angle

CONCLUSION

To implement best building practices, fulfill the continuous insulation requirements of certification programs, and comply with NYC Energy Conservation and Construction Code, SWA recommends limiting the number of shelf angles in the construction of the envelope. This will help limit upfront material and long-term maintenance costs.

SWA also recommends off-setting the shelf angle to reduce the thermal bridging these steel elements create. Fewer shelf angles means that there are less obstacles imposed on exterior insulation, resulting in less thermal bridging. Limiting the impact of shelf angles produces a more robust and insulated envelope that will, in turn, positively impact the energy performance of the building and comfort of its occupants.

SWA would like to thank Robert Murray for his assistance with this article.

Robert J. Murray, P.E., LEED AP, Principal

Murray Engineering, PC

307 Seventh Avenue, Suite 1001

New York, NY 10001

Telephone: 212.741.1102

Email: rmurray@murray-engineering.com

REFERENCES

1. Anderson, J., D’Aloisio, J. DeLong, D., Miller-Johnson, R., Oberdorf, K., Ranieri, R., Stine, T., and Weisenberger, G. “Thermal Bridging Solutions: Minimizing Structural Steel’s Impact on Building Envelope Energy Transfer.” American Institute of Steel Construction. Modern Steel Construction, 1 Mar. 2012. Web. <http://msc.aisc.org/globalassets/modern-steel/archives/2012/03/2012v03_thermal_bridging.pdf>.

2. FERO: Engineered Construction Technologies. Product Catalogue. Edmonton: FERO: Engineered Construction Technologies, 2014. Web. <http://www.ferocorp.com/pages/fast/fast.html>