Whether code built or energy efficient, if your new home has a poured concrete foundation and floor slab, please pay particular attention to the following. While older, leaky homes result in low interior moisture levels (thus the desire for humidifiers on central furnaces); newer, tighter homes will typically have relative humidity levels in the 25-50% range naturally.

Moisture from construction materials in new homes must be managed to avoid problems like interior condensation and mold.

In some cases, there is a need to actually dehumidify to maintain relative humidity below 50% during the winter. In the first 1-2 years after the home is built, concrete foundations expel massive amounts of moisture as part of the concrete curing process called “hydration”. As the concrete cures, some of the water in the concrete mix reacts chemically with the portland cement and forms the hardened concrete, and some of the water evaporates to the surrounding air. The exterior water resistant/proof coating on the below grade portion of the foundation prevents moisture from escaping that way. Typically only a 1-2 foot tall area along the perimeter of the above-grade portion of the foundation is available for drying to the exterior. It is more likely that the moisture will be expelled to the interior of the home and therefore, must be managed to prevent deleterious moisture-related problems such as condensation, mold, wood rot, etc. Framing lumber also contributes: lumber that starts out kiln-dried at 18% moisture levels, will eventually end up at 6%.

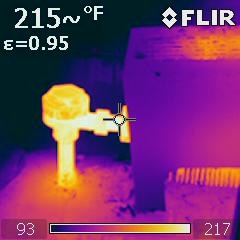

How to deal with that moisture? Here is that cheap investment alluded to: an ENERGY STAR dehumidifier with a built-in humidistat. This unit should be plumbed to a drain to allow continual operation (without having the occupants empty a bucket). In addition, the dehumidifier should be installed in the basement or crawlspace as soon as the structure has been enclosed and power is available. In terms of the construction process, it is recommended that the foundation be the last item to be insulated to allow for the internal construction moisture to be removed prior to enclosing. After a year or two of occupancy, construction material moisture levels will become stabilized at “normal” levels. In the interim, remember to “build-tight and ventilate right”, but also manage that construction moisture.